Automatic Grain Store

The turning, handling and cleaning of grain all in the same system.

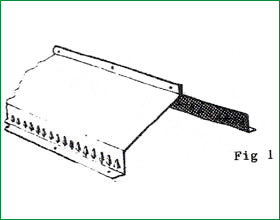

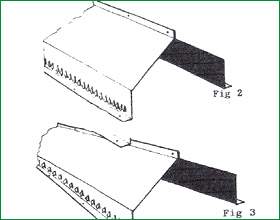

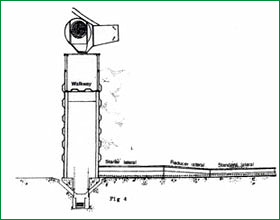

The key to the automatic Lacey system is the new on floor Lacey lateral with specially designed louver openings (figure 1). These allow ventilation and movement of floor-stored crop, when fed by a fan through the central main air duct. An elevator and upper and lower conveyors complete the automatic unit which needs minimum operator attention to handle up to 60 tonnes per hour. For the standard Lacey M20 crop (20m wide) starter and reducer laterals (Fig 2 and 3) are also required to maintain necessary air velocity.

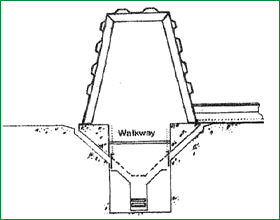

The Lacey standard main air duct is incorporated in the automatic system. A walkway is incorporated above the duct with handrails on, which a grain distributor can be located. (Fig 4) the distributor is strongly recommended for input of crop into the store.

The Lacey on-floor laterals are supplied in sections and types to suit different widths of building. They are reinforced for extra strength. The angled louvers in the walls of the laterals direct the air flow to sweep the stored crop along the floor and into the lower conveyor through the chutes between the laterals.

To empty a store a limited number of entry chutes into the lower conveyor are opened. The grain will initially fall by gravity but then the velocity of air will sweep the crop along the floor, through the chutes into the conveyor and to the pit.

Lacey produce an alternative duct for commercial use. This can be used with the automatic system or with standard on floor systems, where grain is stored in excess of 5m depth.

If you would like to find out more information please contact us on 01223 880385.

Please note:

The capacity of the turning is dependent on the size of the conveyors. This can be up to 100 tonne per hour.